Shaping tough materials like tungsten carbide or hardened steel is challenging for traditional machining methods. These methods often struggle with precision and efficiency, leading to tool wear and limited capabilities.

EDM (Electrical Discharge Machining) solves this problem by using electrical discharges to erode the material, enabling precise cutting of even the toughest materials. And this is the reason why this method is quite popular in processes like mold and die manufacturing.

In this article, we are going to talk about EDM wire cutting in detail.

What is EDM Wire Cutting?

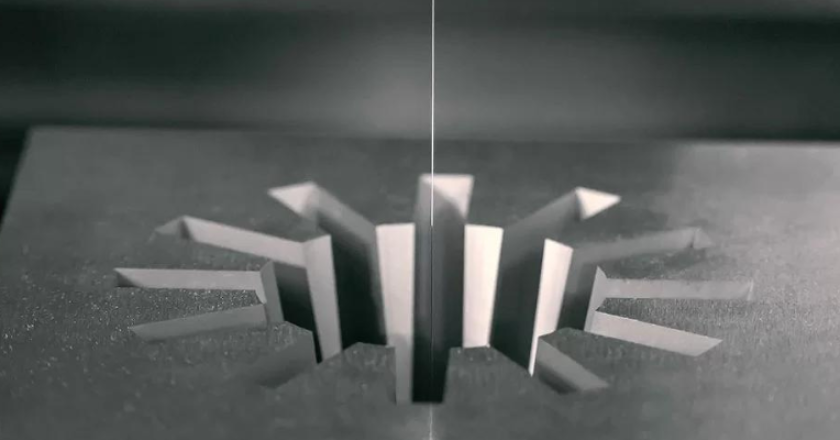

EDM Wire Cutting is a precision machining process that uses electrical discharges (sparks) to cut and shape conductive materials. In this process, a thin, electrically charged wire acts as the cutting tool.

The wire never touches the material; instead, it generates sparks that erode the material, allowing for extremely accurate and intricate cuts.

It is used to create sharp corners, V-shaped features, and intricate details that high-speed milling can’t achieve, such as piercing features, complex mold cavities, and fine internal contours.

For ultrasonic welding, energy directors should be at least 0.020 inches (0.5mm) with a 1:1 width-to-depth ratio for features under 0.04 inches (1.0mm).

Key Components Involved:

- Wire: A thin, electrically conductive wire, usually made of brass or copper, which is continuously fed through the machine to maintain a fresh cutting edge.

- Dielectric Fluid: A fluid, typically deionized water, that surrounds the wire and workpiece. It acts as an insulator, cools the cutting area, and flushes away the eroded material (debris).

- Power Supply: Provides the electrical energy that generates the sparks between the wire and the workpiece, essential for the cutting process.

Step-by-Step Process for EDM Wire Cutting

Let us now take a look at the process of EDM cutting in detail.

1. Setup

Securing the Workpiece

The workpiece is carefully positioned and fixed into the wire EDM machine’s holding fixture. This setup ensures the workpiece is stable and aligned to prevent any movement during the cutting process.

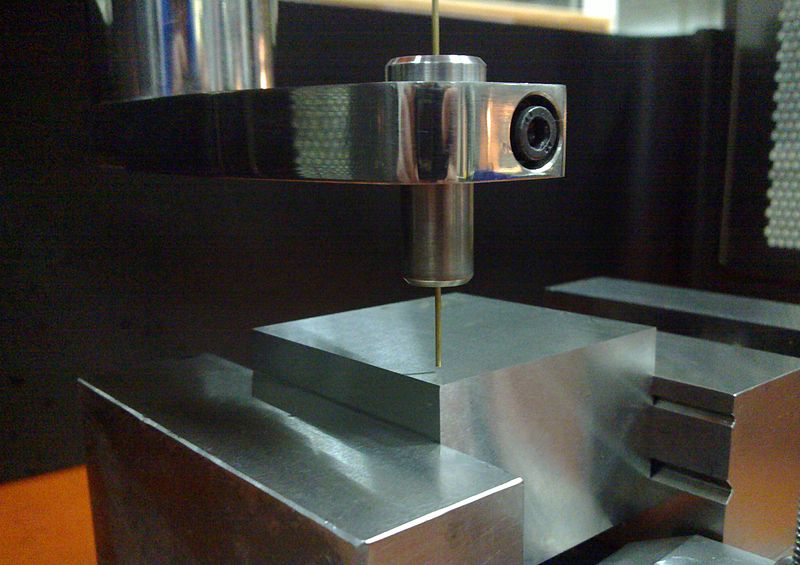

Threading the Wire

A thin, electrically conductive wire, typically made of brass or stratified copper, is threaded through the EDM machine and aligned with the workpiece. The wire is placed under precise tension to ensure it follows the intended cutting path accurately. Usually, the diameter of this wire is between 0.1 and 0.3 m.

2. Cutting Process

Role of Dielectric Fluid

Dielectric fluid, usually deionized water, floods the cutting area. This fluid performs several crucial functions: it insulates the electrical discharges, cools both the workpiece and wire and helps flush away the material eroded by the cutting process.

This ensures clarity and precision in the cutting zone.

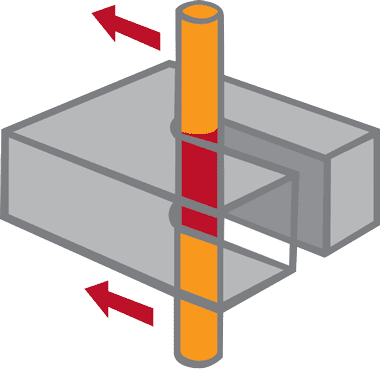

Controlled Wire Movement

Using CNC controls, the wire is moved along the programmed path with high precision. Electrical discharges (sparks) occur between the wire and the workpiece, gradually eroding the material to shape it according to the specified design. The dielectric fluid continuously removes the debris from the cutting area to maintain accuracy and prevent any obstruction. There is never any mechanical contact between the electrode and the workpiece to prevent damage.

3. Finishing

Process Conclusion

After the cutting is completed, the EDM wire cut machine halts, and the wire is retracted from the workpiece. This signals the end of the cutting phase.

Post-Processing

The workpiece is then removed from the EDM wire cut machine and inspected for accuracy. If needed, additional finishing processes, such as deburring or polishing, are performed to achieve the final surface quality and detail of the workpiece.

Top Custom part manufacturers like Dainsta employ proper quality checks on the parts during the process ensuring the end product meets the right dimensions and performs perfectly under adverse conditions.

Advantages of Wire Cut EDM Cutting

Wire cut EDM method is beneficial in terms of achieving high accuracy while cutting complex shapes and hard materials. However, there are some other advantages of this method, which are as follows:

No Mechanical Forces:

Since EDM uses electrical discharges rather than mechanical forces, it can machine hard and brittle materials without causing mechanical stresses or deformation.

High Precision and Accuracy:

EDM (Electrical Discharge Machining) can achieve extremely fine tolerances and complex geometries that are difficult to machine using traditional methods.

It’s ideal for creating intricate details and sharp corners.

Ability to Machine Hard Materials:

EDM (Electrical Discharge Machining) is highly effective for machining materials with high hardness, such as tool steels and superalloys, which are challenging for conventional cutting methods.

Complex Shapes:

It can create complex shapes and intricate features, including small holes, deep cavities, and fine details that are often beyond the capability of traditional machining.

Minimal Tool Wear:

The process doesn’t involve direct contact between the tool and the workpiece, reducing tool wear and extending tool life.

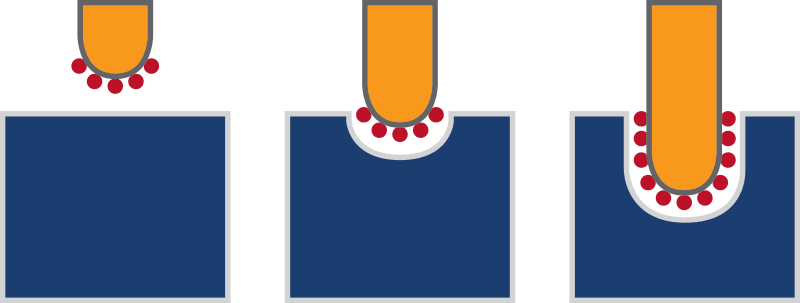

When use Small Hole EDMs?

Small Hole Electrical Discharge Machining (EDM) is a precision technique used to create tiny holes, ranging from 0.010″ to 0.118″ (0.25mm to 3.0mm) in diameter.

It is ideal for applications such as drilling cooling holes in turbine blades, producing intricate ventilation openings, or crafting complex designs where traditional machining methods fall short.

This technique is crucial in industries like aerospace, medical devices, and electronics, where precision and minimal thermal impact are essential.

Conclusion

Wire-cut EDM (Electrical Discharge Machining) offers precision and versatility for complex metal-cutting tasks. It excels in creating intricate shapes and high-tolerance components, making it invaluable in industries such as aerospace, automotive, and toolmaking.

The technology’s ability to cut conductive materials with minimal distortion and a smooth finish enhances production efficiency and product quality.

To achieve optimal results, it’s essential to have skilled operators who understand the nuances of this technology. For reliable and accurate outcomes, it’s important to engage with expert CNC Wire cut service providers.

Want high-performance parts with high precision and accuracy?

Let Dainsta get you started.