Metal parts endure harsh conditions, which often lead to corrosion and wear and tear. Metal finishing is a viable solution to safeguard against these problems. In the metal finishing process, a thin layer of coating material is deposited on the metal part.

These layers serve as a sacrificial coating, absorbing wear and preventing direct contact between the substrate and abrasive particles or corrosive agents.

So, whether a well-finished metal part is used under high-temperature conditions like a car engine or in cutting tools, it’s less likely to rust or deform.

However, the best type of finishing depends on various factors like a part’s usage and specific durability requirements. And that’s exactly why it’s important to learn different kinds of metal finishing methods.

In this article, we are going to talk about metal finishing techniques in detail.

Importance of Metal Finishing in Product Quality

Metal finishing significantly impacts product quality across various industries for several reasons, such as:

Protection Against Corrosion and Wear

Metal finishing techniques create a protective barrier on surfaces, shielding them from corrosion, oxidation, and wear. By preventing rust and degradation, metal parts retain their integrity and functionality over extended periods, enhancing product durability and reliability.

Enhancement of Aesthetics

Metal finishing enhances the visual appeal of products, contributing to their overall aesthetics and marketability. Whether it’s a polished chrome finish on automotive parts or a decorative anodized coating on consumer electronics, aesthetically pleasing surfaces create a positive impression on customers and strengthen brand identity.

Consistency and Precision

Proper metal surface finishing ensures uniformity and precision in surface characteristics, leading to consistent product quality. Finishing processes can achieve tight tolerances, smooth surface finishes, and uniform coatings, ensuring that each component meets specified standards and performs reliably in the field.

Different Metal Finishing Techniques

Since each metal part demands a distinct finish for better performance, let’s take a look at these popular finishing methods to better understand their applications. And some advantages in quality enhancement.

1. Grinding

Grinding in metal finishing involves using abrasive materials to remove surface material from a workpiece. This is typically achieved by rotating a grinding wheel against the surface of the metal, applying pressure to remove excess material, and achieving the desired finish.

It helps to achieve smooth surfaces, remove imperfections, and prepare the metal for further finishing processes or assembly. Precisely, it leads to:

- Fast Stock Removal

- Improved Surface Integrity

- Dimensionally Accurate parts

However, in case of intense friction, Grinding could lead to thermal expansion, which may eventually lead to distortions and surface irregularities. Strategies including coolant/lubricant use could help in minimizing distortion.

Let us understand more finishing nuances, such as RMS, Grit Size, Ra, and Rz, to achieve a perfect finish in a given case:

| Grit Size | RMS | RA | RZ | Min Corner Radius |

|---|---|---|---|---|

| 60 | 24-32 | .50-.60 | 3.5-5.0 | .020 |

| 80 | 18-24 | .40-.50 | 2.5-3.5 | .016 |

| 100 | 16-18 | .20-.40 | 2.2-2.5 | .012 |

| 120 | 9-16 | .20-.35 | 1.3-2.2 | .008 |

| 140 | 5-9 | .10-.20 | .65-.13 | .005 |

| 160 | 4-5 | .08-.10 | .55-.65 | .004 |

| 180 | 2-4 2 | .03.-0.8 2 | .32-.55 2 | .003 |

| 200 | 1-2 2 | .02.-0.5 2 | .16-.32 2 | .002 |

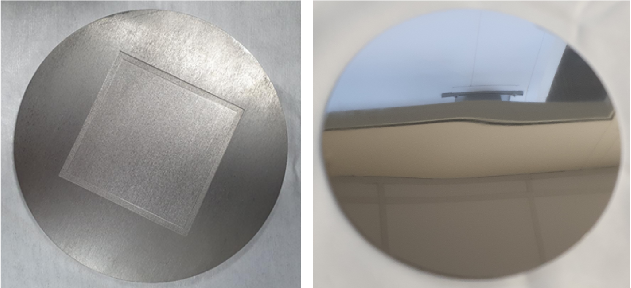

2. Sanding/Blasting

Sanding or blasting in metal finishing involves using abrasive materials to smooth surfaces and prepare them for further finishes. It removes imperfections and creates a uniform texture, improving the overall appearance of the metal component.

Sanding achieves this by physically rubbing abrasive materials against the surface, while blasting involves directing abrasive particles at high velocity onto the metal surface. Both methods are commonly used in various industries for surface preparation and refinement.

Some of the benefits of this method include:

- Improved surface textures

- Better Removal of Surface Contaminants

- Relieved Residual Stresses

This method can produce a significant amount of dust when it comes into contact with the surface being treated. Plus, for large areas, it can be challenging to ensure uniform coverage and consistency in the sanding or blasting process.

3. Pickling and Passivation

These Chemical Finishing Techniques are crucial metal finishing processes, particularly for stainless steel components. Pickling involves the removal of impurities and surface oxides using acidic solutions, ensuring a clean surface free from scale and contaminants.

Following pickling, passivation enhances the corrosion resistance of the metal by forming a protective oxide layer through immersion in oxidizing solutions.

This process creates a chromium-rich surface layer, providing a barrier against corrosion and maintaining the integrity of stainless steel components in harsh environments.

Together, pickling and passivation ensure the cleanliness and corrosion resistance of metal surfaces, contributing to the finished product that has:.

- Surface Cleanliness for further Preparation

- Enhanced Corrosion Resistance

- Extended Lifespan

In this process, proper ventilation is necessary to mitigate exposure to hazardous fumes.

4. Electroplating

It is one of the common methods used in metal finishing. It involves the deposition of a metal coating onto a substrate through an electrochemical process. Typically, after a metal part undergoes CNC milling, electric current is used to deposit metal ions from a solution onto the surface of the workpiece.

This method generally results in:

- Corrosion resistance

- Improving the durability of the substrate

- Enhancing aesthetic appeal

Because of the above-mentioned reasons, it is recommended for automotive, electronics, and jewellery manufacturing industries.

5. Polishing and Buffing

Polishing and buffing in metal finishing are mechanical processes aimed at improving the surface texture, appearance, and shine of metal components. It involves the use of sandpaper or polishing compounds to remove surface imperfections, scratches, and oxidation, leaving behind a smooth and lustrous finish.

Buffing, on the other hand, utilizes soft rotating wheels or brushes to further refine the surface and enhance its shine. A metal part made in these processes features:

- Highly reflective surface

- Electrical resistance

- High durability

The metal parts are lustrous and electrically resistant, so they are commonly employed in industries like automotive, jewellery, and metal fabrication.

6. Anodizing

Anodizing involves immersing the aluminium in an electrolyte solution. And then the current is passed through it. This metal surface treatment method causes oxygen ions to combine with the aluminium surface, creating a thick and durable oxide layer.

It enhances the surface of aluminium by forming a protective oxide layer. This layer improves:

- Corrosion resistance

- Metal Durability

- Surface aesthetics.

Anodizing can also involve dyeing the oxide layer to achieve various colours for decorative purposes. Dainsta uses this process to create anodic films for several cosmetic effects.

7. Powder Coating

It is a dry finishing process where finely powdered particles are electrostatically charged and sprayed onto a metal surface.

The charged particles adhere to the surface and are then heated, causing them to melt and form a protective and decorative coating. This

This coating is durable and resistant to chipping, fading, and corrosion.

Some features of a powder-coated metal include:

- Heat resistance

- Electrical conductivity

- Uniform coverage

It is mainly used across various industries for applications ranging from automotive parts and household appliances to furniture and architectural components.

Final Words

Metal surface finishing techniques play a crucial role in enhancing metal parts’ durability, appearance, and performance. They are essential for protecting against corrosion, improving surface integrity, and achieving desired aesthetics.

However, while working with metal finishing it’s important to follow the best practices like ensuring proper ventilation and using safety equipment. Additionally, Outsourcing to a reliable manufacturing partner offers access to expertise, advanced equipment, and cost-effective solutions.

Need help choosing the right finishing technique for your specific application?

Partner with Dainsta for expert guidance and support.