Steel is an alloy of iron and carbon, typically containing elements such as manganese, chromium and nickel. It is relatively easy to machine using various CNC steel machining techniques. Moreover, some additive manufacturing techniques, such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), can 3D print steel parts directly from metal powders.

Because of its exceptional strength, durability, and versatility, it is one of the most commonly used in manufacturing mechanical parts.

Dainsta deals in 4 main types of steel and a wide range of grades. Our experts can guide you in choosing the best steel grade for your needs. With their help, you’ll select the grade that ensures optimal performance for your application.

Alloy steel combines carbon steel with alloying elements like chromium, manganese, and nickel to enhance strength, toughness, and wear resistance.

Alloy steel 1.7131 is a low-alloy steel. It offers good hardenability, strength, and wear resistance. Because of its high machinability, it is used in the automotive, machinery, and gear manufacturing industries.

Alloy steel 4340 exhibits high weldability, toughness, and

wear resistance. Its mechanical properties can be enhanced with heat treatments. It is mostly used in high-performance and demanding environments.

Alloy steel 1215 is a low-tensile carbon steel which is easily machinable. It offers excellent chip breakability and a lustrous finish. Its mechanical strength can be enhanced with heat treatments.

Alloy steel 4140 offers excellent strength, toughness, and fatigue resistance. It is a versatile grade of steel that is mainly used to develop gears, axles, crankshafts, and hydraulic components.

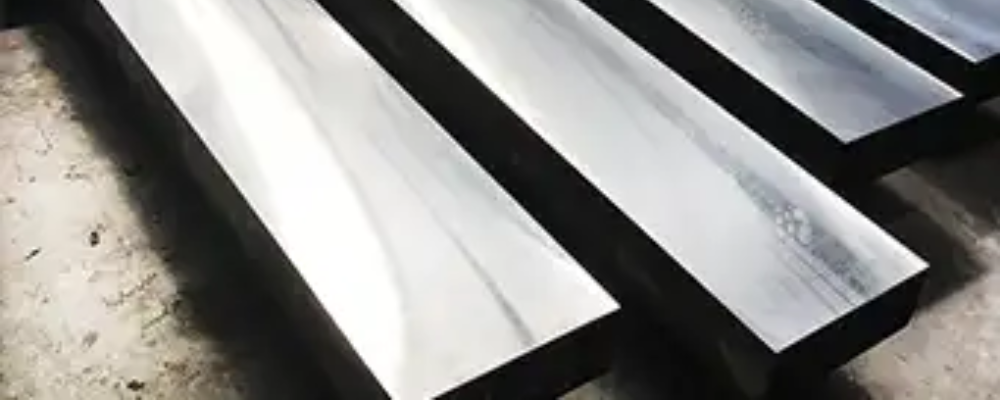

Tool steel, characterized by its high hardness and resistance to abrasion and deformation, is used for making cutting tools, dies, and molds.

Tool steel D2 is a high-carbon and chromium cold work tool steel with excellent wear resistance and toughness. It offers high hardness and good dimensional stability. Plus, it offers resistance to deformation under high temperatures as high as 425 degrees Celsius.

Tool Steel A2 is an air-hardening, medium-alloy, cold work tool steel with higher wear resistance. It exhibits high dimensional stability and good machinability in CNC tool steel machining processes. It is ideally used for forming dies or for components with tight tolerances.

Tool steel O1 is a general-purpose, oil-hardening, non-deforming tool steel. This steel grade is popular because of its wear resistance and hardness of up to 65 HRC.

Tool steel A3 is a medium-alloy, air-hardening tool steel. It exhibits high hardness temperature resistance and can be machined easily. Because of these factors, it is ideal for cutting tools, dies, and punches.

Tool steel H13 is air-hardening tool steel with high impact strength and wear resistance. Its dimensional stability and resistance to deformation under high-impact loads make it ideally suited for tooling applications.

Tool steel S7 is a hot-work tool steel with high heat resistance, offering toughness and wear resistance. Its ability to withstand thermal cycling and maintain hardness at elevated temperatures makes it suitable for producing parts with complex shapes.

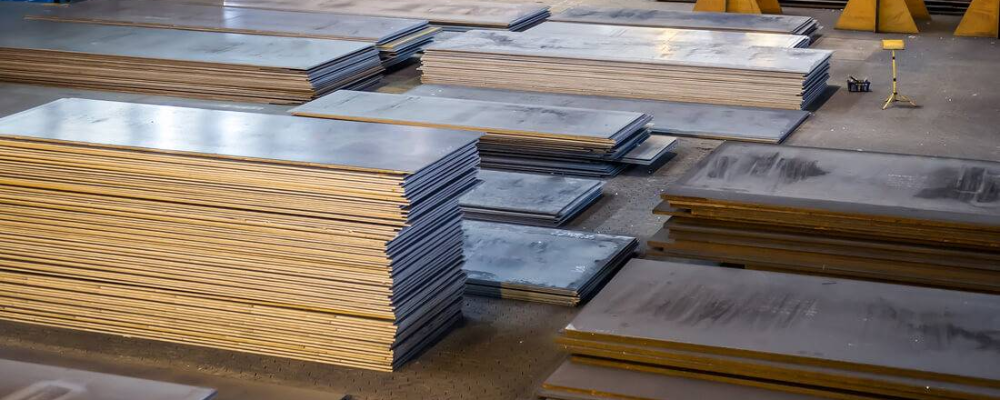

Carbon steel is an iron-carbon alloy known for its high hardness, strength, and wear resistance, used widely in construction and manufacturing.

C45 is the steel equivalent to EN 1.1191. This kind of steel offers hardenability and strength. It has high electrical conductivity but low thermal conductivity.

We use Carbon A36 steel for its excellent weldability, machinability, and high strength, making it ideal for structural applications and general-purpose use.

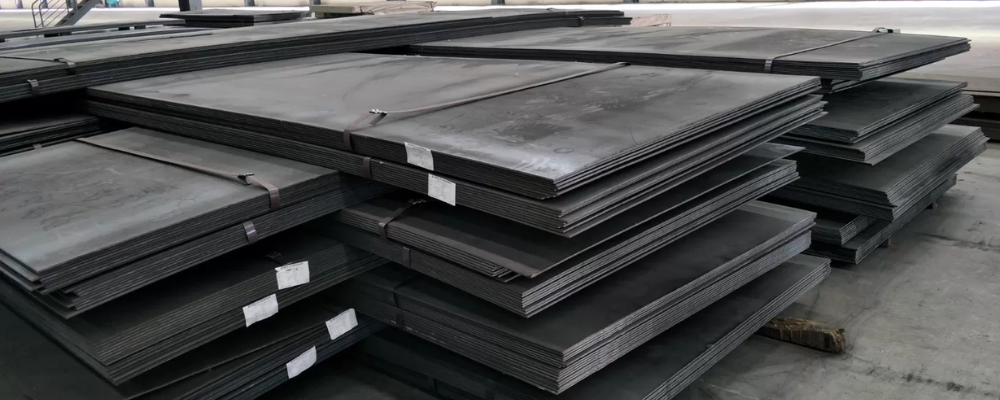

Mild steel, a low carbon steel, offers excellent ductility, weldability, and machinability, making it ideal for general engineering and construction applications.

Mild steel S355J2 is a structural steel with a minimum yield strength of 355 MPa. It offers good weldability as well as high impact resistance.

Mild steel 1018 is a low-carbon steel with high weldability, machinability, and formability. Manganese enhances its overall strength, making it suitable for parts demanding less strength, such as shafts or bolts.

Mild steel 1045, or medium carbon steel, contains approximately 0.45% carbon. It offers good machinability, weldability, and wear resistance. It can be heat treated to achieve higher hardness and strength.

Mild Steel S235JR is a low-carbon structural steel and is valued for good plasticity, toughness and weldability. It's used for structural components and pipes in construction, and automotive industries.

Mild steel A36 is a carbon structural steel that has a yield strength of 250 MPa (minimum). However, it is less corrosion-resistant. It is suitable for structural components, plates, and general engineering applications.

Mild steel S275JR offers good weldability, formability, and machinability. It has a similar composition to S235JR but ranks better in terms of strength. CNC machined mild steel is used to make pipes, and machinery parts.