Want to meet tight deadlines and keep production costs in check without compromising quality? It is pretty much possible. However, you have to make sure you initially follow the right and error-free process. And that’s exactly where DFM comes into play.

With DFM, you can optimize product designs for efficient manufacturing, reduce costs, and improve quality throughout production.

In this article, we are going to explore DFM in detail, specifically focusing on how it is important in the entire product lifecycle.

Understanding DFM

Designing for Manufacturing and Assembly (DFM or DFMA) involves optimizing the design of your product for its manufacturing and assembly process, merging the product’s design requirements with its production method. Employing Design for Manufacturing tactics reduces the cost and difficulty of producing a product while maintaining its quality

Principles of DFM

Understanding the 5 principles of DFM can help you go a long way. Let us take a look at these and their benefits:

Simplicity in Design

Complex designs often result in increased manufacturing costs, longer production times, and higher chances of errors. By simplifying the design, manufacturers can streamline the production process, reduce material waste, and enhance overall product reliability. Emphasizing simplicity also makes maintenance and repair easier, leading to better user experiences and lower lifecycle costs.

Standardization of Components

Using standardized components not only reduces the complexity of manufacturing but also enables economies of scale in procurement and production. It minimizes the need for custom tooling and specialized machinery, leading to cost savings and shorter lead times. Standardization enhances interoperability, simplifies inventory management, and facilitates future product iterations and upgrades.

Design for Assembly (DFA)

Considerations such as part orientation, symmetry, and modularity can significantly impact assembly efficiency. As a manufacturer, you can reduce labour costs, minimize assembly errors, and accelerate time-to-market by designing easy-to-handle and assembled parts. Features like snap fits, self-locating fasteners, and modular sub-assemblies simplify the assembly process and enhance overall product quality.

Material Selection and Optimization

Manufacturers can reduce material costs by considering factors such as material availability, machinability and environmental impact. Plus, they can improve sustainability by choosing the right materials and optimizing material usage.

Moreover, selecting materials with suitable properties enhances product durability, functionality, and aesthetics. It ultimately increases customer satisfaction and brand reputation.

Design for Cost (DFC)

By proactively addressing cost considerations in the design phase, manufacturers can optimize product profitability, remain competitive in the market, and meet target price points. Continuous refinement of the design based on cost feedback enables iterative improvement and long-term cost optimization.

Challenges in a Product Lifecycle

At various stages of the product lifecycle, several challenges are always there. Let us take a look at each one of them.

Cost Overruns

Inefficient manufacturing processes can lead to higher expenses, such as increased labour costs due to longer production times and material waste resulting from suboptimal designs. These overruns strain budgets and erode profit margins.

Quality Issues

Variations in manufacturing processes can introduce defects and inconsistencies in the final product, compromising its performance and reliability. As per some research, 12% of the project cost is lost due to parts delivered with quality issues.

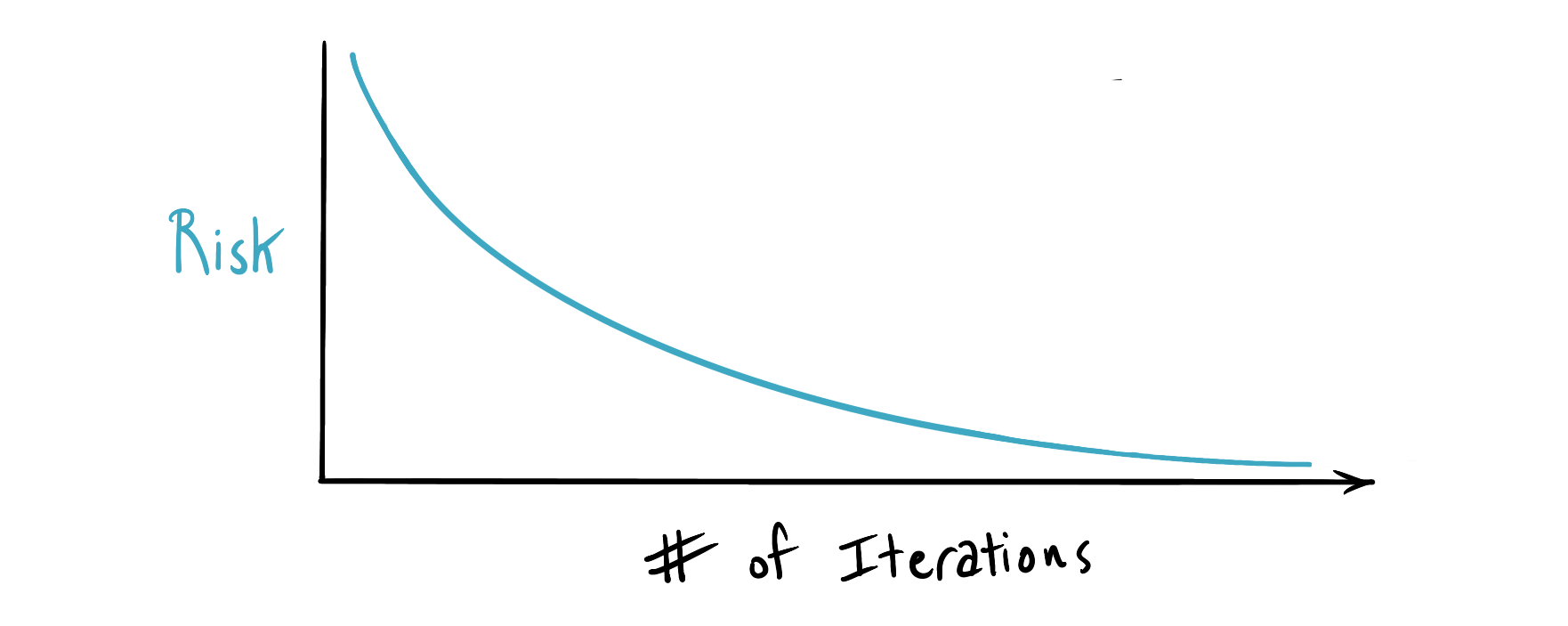

Design Iterations

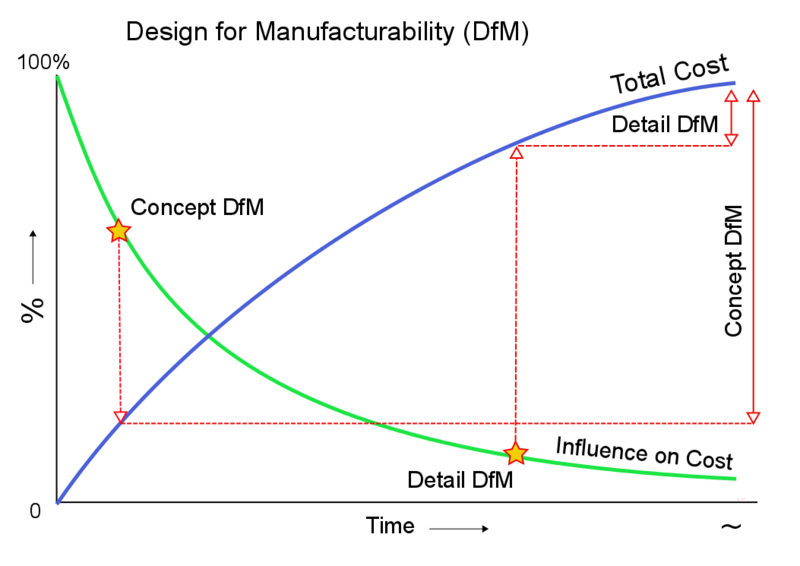

Identifying manufacturability issues late in the design process often requires iterative revisions to the product design. These iterations extend the development timeline and incur additional costs for prototyping, testing, and redesigning.

Production Delay

Unexpected disruptions in production, such as equipment breakdowns or shortages of critical components, can lead to delays in meeting production schedules. These delays ripple through the supply chain, impacting inventory levels, customer orders, and revenue generation.

This is why early detection of design challenges allows for more efficient problem-solving and reduces the need for extensive revisions later in the process.

How can DFM Solve These Issues?

As we have discussed some common challenges, it’s time to understand how DFM can be used to solve these problems. Here’s how the DFM process contributes to the manufacturing process:

Cost Efficiency

DFM simplifies designs, standardizes components, and optimizes production processes. This reduces material waste and minimizes expensive rework. As a result, a reduction in production costs can be observed.

Enhanced Product Quality

DFM ensure that designs are optimized for CNC machining processes. This includes simplifying geometries and minimizing sharp internal corners. Plus, it involves avoiding features that are difficult or costly to machine.

By designing products with manufacturability in mind, manufacturers can ensure smoother and more consistent manufacturing processes, leading to higher product quality.

Streamlined Production Workflow

DFM’s early identification and resolution of potential manufacturing bottlenecks and supply chain risks enable smoother production workflows. This reduces the likelihood of delays, and efficient production can be ensured.

Accelerated Time-to-Market

DFM’s focus on early detection and resolution of manufacturability issues minimizes the need for extensive design revisions later in development. Hence, it aids in products to reach the market faster.

Improved Supply Chain Resilience

DFM’s emphasis on supply chain resilience through strategies like supplier diversification and risk mitigation ensures uninterrupted production despite disruptions such as supplier issues.

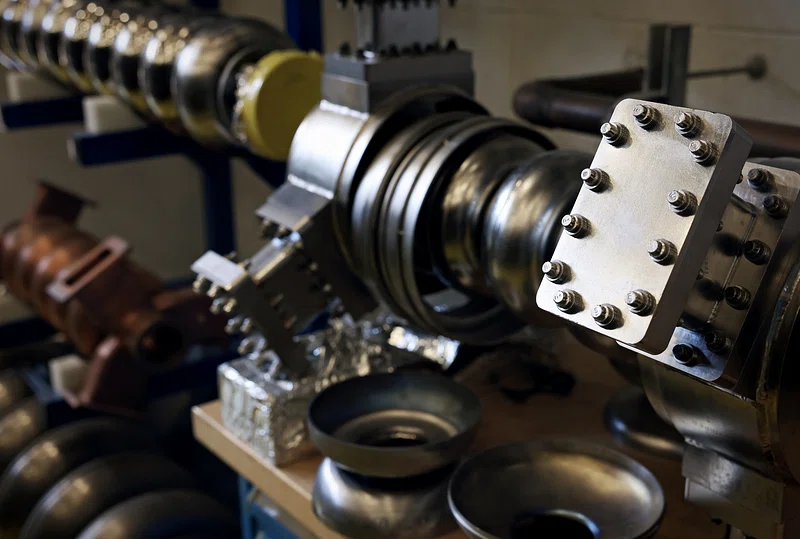

Best Practices for DFM in Making CNC Machined Parts

To make the most out of Design for Manufacturing while creating CNC machined parts, you can consider the following practices:

Wall Thickness Considerations

Keep wall thicknesses greater than 0.02″ to prevent brittleness and breakage, which is particularly important for aerospace, automotive, and transportation applications where weight reduction is a priority.

Tolerance Considerations

Avoid non-critical tolerances less than +/- 0.005″ to prevent the need for specialized tools and extra setup time, which can increase costs and lead times without significant functional benefits.

Avoidance of Deep Pockets with Sharp Corners

Design internal corners with radii of at least 0.0625″ to facilitate machining and avoid the need for long-reach tools, which can drive up costs and lead times. Specialized tooling may sometimes be necessary to machine deep pockets with sharp corners.

If you are outsourcing your project, consult with the right manufacturing partners like Dainsta, who can provide suitable tooling options for your specific application.

Limiting Pocket Depths

Restrict pocket depths to no greater than 12 times the smallest corner radii to enable quicker and more cost-effective machining with standard tooling, minimizing the risk of tool breakage.

Simplicity Over Aesthetics

Prioritize functionality over complex aesthetic features to reduce costs and lead times associated with machining intricate geometries that are not critical to the part’s functionality.

Preference for Chamfers

Design exterior features with chamfers instead of fillets whenever possible to simplify machining processes and minimize programming and machining times.

Wrapping Up

Summing up, the DFM process can help you optimize the design of your product. Implementing DFM principles throughout the product lifecycle, especially in CNC machining, can empower manufacturers to meet tight deadlines and control production costs. This ultimately leads them to deliver high-quality products to the market efficiently.

Looking for a reliable manufacturing partner to deliver high-quality custom mechanical parts?

Let Dainsta help you!