Ever wondered how a smooth, uniform finish is achieved on parts? Bead blasting might just be the answer you’re looking for. This surface preparation technique can effortlessly remove stubborn rust, grime, and paint, leaving surfaces looking brand new.

This is one of the reasons why bead blasting is so popular in industries including automotive, aerospace, manufacturing, and marine.

In this article, we are going to discuss all the ins and outs of bead blasting and its incredible benefits. By the end of this article, you will be able to understand how this technique works.

So, let us get started!

What is Bead Blasting?

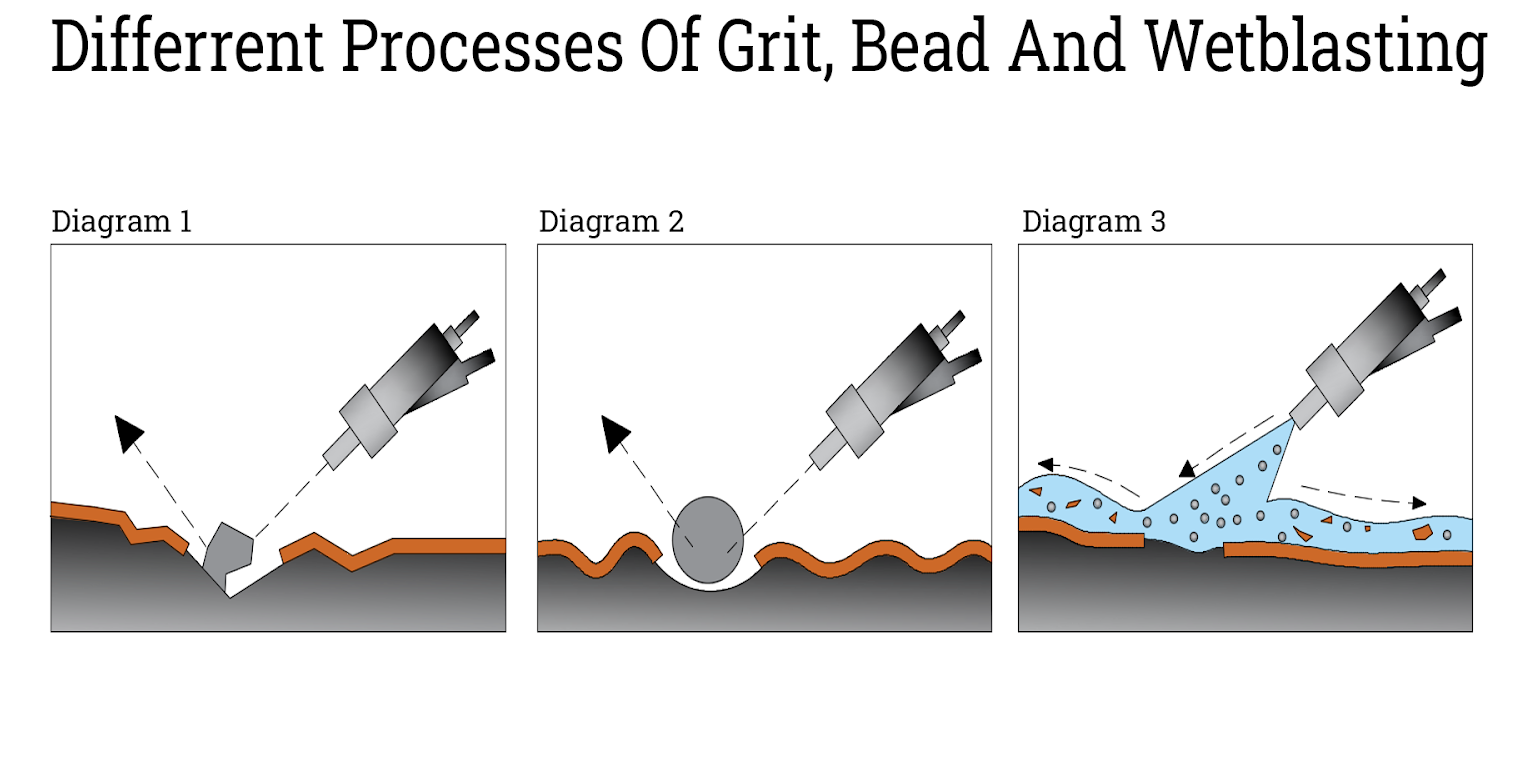

Bead blasting is one of the surface finishing techniques that uses fine glass beads shot at high speed to clean, polish, or prepare surfaces. The process involves a machine or a bead blaster that uses compressed air to propel the beads toward the material.

As a result, this method effectively removes dirt, rust, and old paint, leaving a smooth, uniform finish without damaging the surface. This technique can even texturize plastic or glass surfaces.

Preparation

At first, the part to be bead blasted is cleaned. Following the cleaning, the suitable type and size of abrasive beads are chosen based on the material for the desired finish. Here, the abrasives may include Glass Bead, Steel Shot, Ceramic Shot, Aluminium Oxide, Plastic Media, or even Garnet.

Blasting

Once the abrasives are selected, they are propelled through a specialized blasting gun or nozzle using compressed air or another propellant.

The high-velocity impact of these particles on the material’s surface effectively removes contaminants and creates the desired texture or finish.

Post Blasting

After the bead blasting process, the surface is cleaned to remove any remaining abrasive particles and debris. Finally, coatings or finishes may be applied to protect and enhance the newly treated surface.

Benefits of Bead Blasting

There are a number of benefits associated with bead blasting. Let us discuss this one by one:

Material Preservation

Unlike harsher abrasive methods, bead blasting preserves the integrity of the underlying material by using spherical beads that impact the surface without causing deformation or damage.

Precision Cleaning

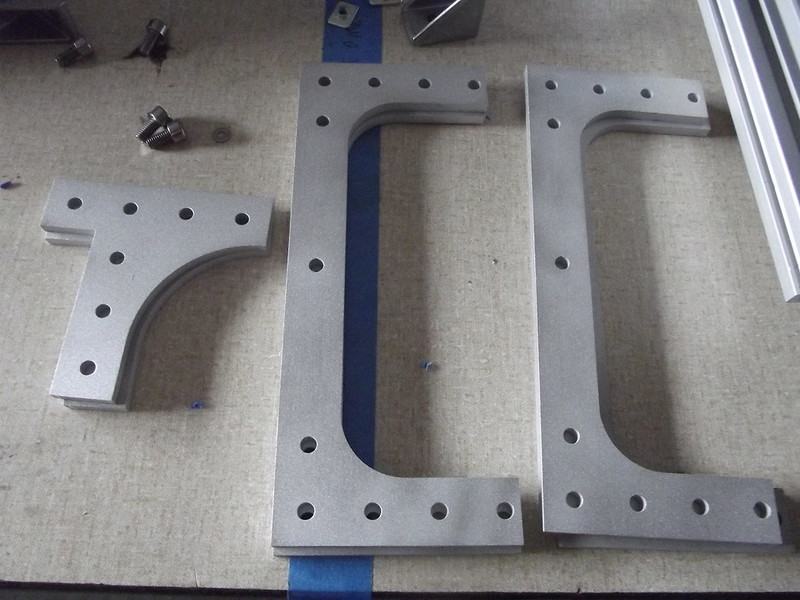

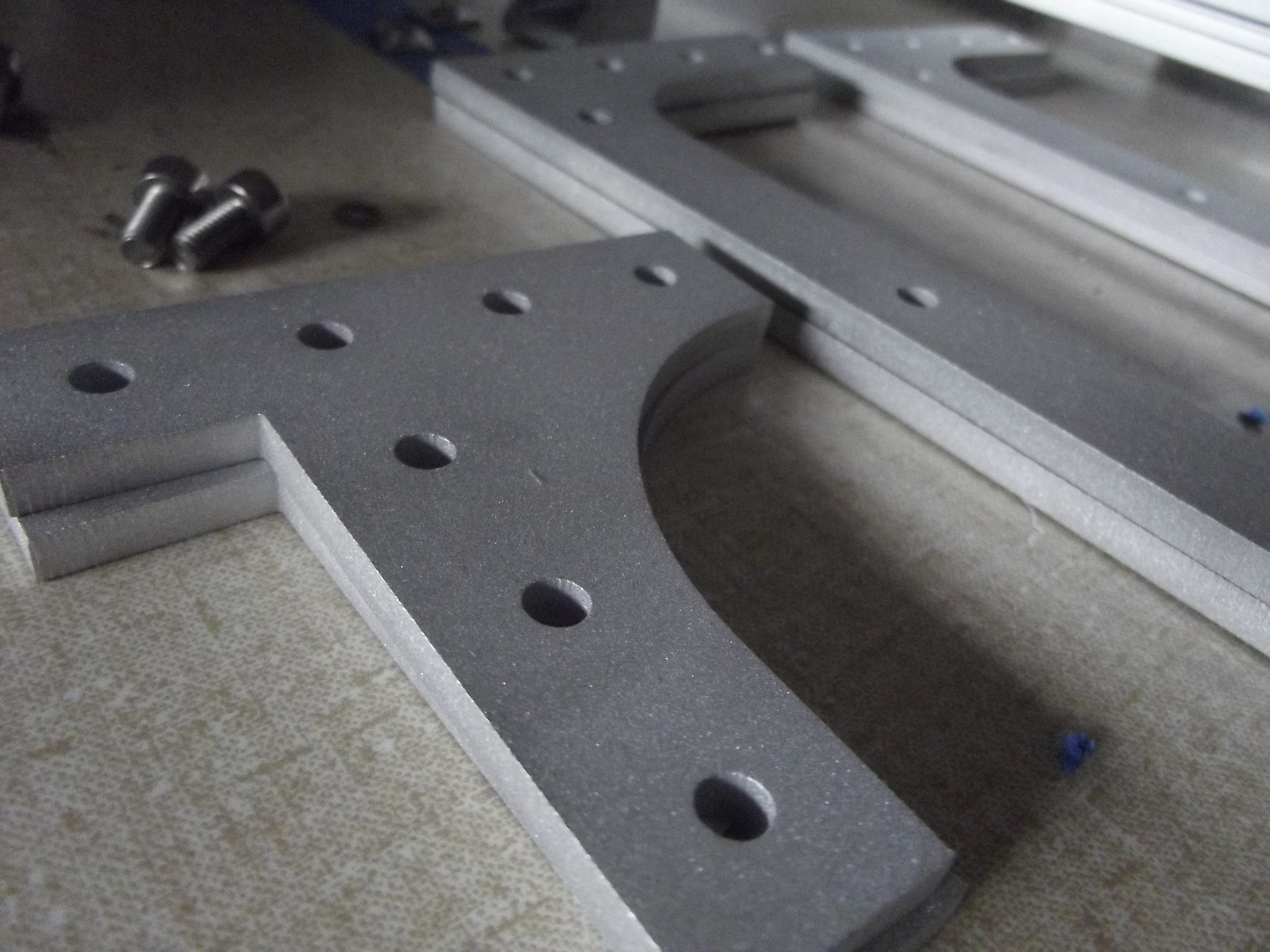

Its controlled abrasive action allows for selective cleaning in intricate or delicate areas, making it suitable for complex parts with varied geometries.

The image above can be a fine example of what a bead-blasted aluminium part looks like.

Environmentally Friendly

The process produces minimal dust and waste, as the beads can be recycled multiple times, reducing overall environmental impact compared to chemical stripping or other abrasive techniques.

Versatility

This kind of blasting can be tailored by adjusting variables such as pressure, media size, and duration, making it suitable for a wide range of materials, including metals, plastics, ceramics, and composites.

When to Choose Bead Blasting?

Here are some scenarios where bead blasting can be the best option for your process:

Removing Corrosion

When metal surfaces are affected by corrosion, bead blasting can effectively remove the corroded layers, restoring the surface to its original condition. It’s commonly used in industries like marine, automotive, and aerospace for this purpose.

Deburring and Surface Finishing

Bead blasting can be used to remove burrs, sharp edges, and surface imperfections from metal, plastic, and ceramic parts. It provides a uniform and consistent finish, improving the aesthetics and functionality of the parts.

Surface Texturing

It can create a textured surface on metals, ceramics, and plastics for aesthetic or functional purposes.

It’s commonly used in architectural applications, signage, and decorative items to achieve unique surface finishes.

Cleaning of Industrial Equipment

Industrial machinery and equipment often accumulate dirt, grease, and other contaminants during operation. Bead blasting can effectively clean these surfaces, restoring them to their original condition and improving performance.

Best Practices for Bead Blasting

Let us take a look at how you can ensure the bead blasting process meets your expectations and provides the desired results:

Selecting Abrasive Media: Choose bead material according to the substrate material and desired finish. Common choices include glass beads, ceramic beads, aluminium oxide, and silicon carbide. Ensure compatibility with the substrate’s hardness and surface integrity.

Pressure Regulation: Precisely control air pressure within the blasting system. The pressure should be optimized based on bead size, material, and the surface being treated. Typically, pressures range between 30-100 psi (2-7 bar).

Nozzle Configuration: Select the appropriate nozzle diameter to regulate the blast pattern and velocity. Nozzle size is contingent on bead size and desired coverage area. A narrow nozzle restricts the blast radius, ideal for intricate detailing, while wider nozzles cover larger surfaces efficiently.

Distance Control: Maintain a consistent standoff distance between the nozzle and the substrate. Typically, this ranges from 6-12 inches (15-30 cm). Deviation from this range can result in uneven blasting and compromised surface integrity.

Surface Preparation: Prior to bead blasting, ensure the substrate is thoroughly cleaned of contaminants such as oil, grease, and rust. Any residue can compromise adhesion and surface finish quality.

Is Bead Blasting Safe for Delicate Materials

When delicate surfaces or environmental concerns pose challenges to traditional bead blasting methods, seeking alternatives becomes imperative. Delicate materials like thin metals or intricate designs risk distortion or damage from bead blasting’s abrasive nature, necessitating gentler approaches.

Additionally, in environments with stringent regulations or enclosed spaces, bead blasting’s generation of dust and debris raises environmental concerns. In such scenarios, turning to the expertise of Dainsta’s professionals can be invaluable.

Wrapping Up

Bead blasting stands as a highly effective surface finishing technique, offering efficient removal of contaminants and coatings across various materials. However, in some exceptional cases, alternative methods may be necessary.

While bead blasting is very good for most applications, situations involving delicate surfaces or specific environmental concerns might warrant exploration of alternatives such as soda blasting or dry ice blasting. It’s imperative to always prioritize the best practices for each unique situation and consult with experts to make informed decisions.

Factors such as surface material, project requirements, and environmental considerations should guide the selection process. By choosing the most suitable method and seeking expert advice when needed, optimal results can be achieved while minimizing risks and ensuring efficiency.

Looking for surface finishing services for your custom mechanical parts? Let Dainsta get you started